Skip to content

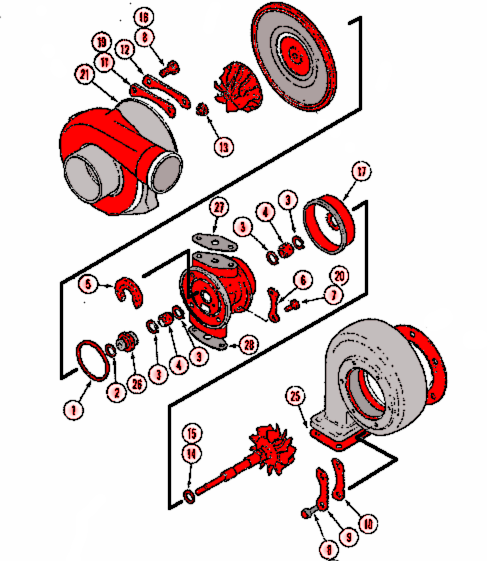

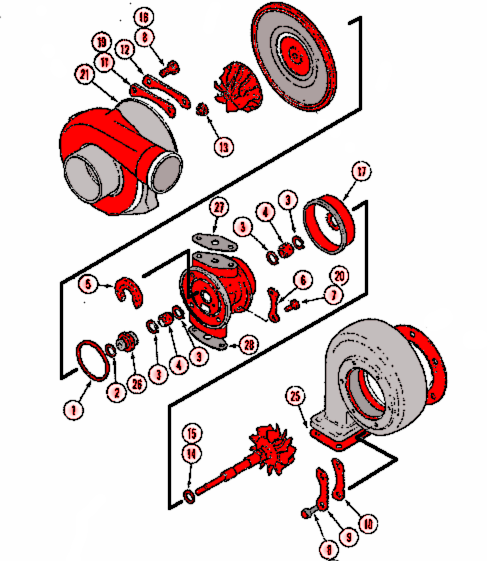

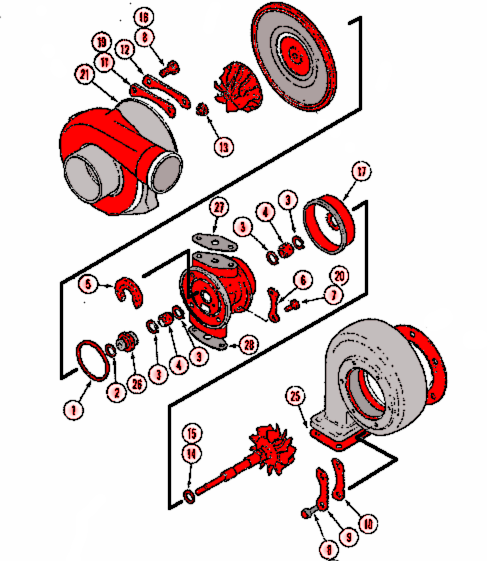

- O Ring (seal plate)

- Piston Ring or Carbon Seal (comp side)

- Snap Ring (bearing)

- Bearing (journal)

- Bearing (thrust)

- Lockplate - if required

- Bolt

- Bolt

- Lockplate - if required

- Clamp plate

- Lockplate - if required

- Clamp plate - on T-4 models

- Shaft Nut

- Piston Ring

- Piston Ring

- Bolt

- Heat Shield

- Seal Plate

- Alt

- Alternate bolt

- O Ring or Gasket

- Compressor Wheel

- Turbine shaft

- Bearing housing

- Flange gasket (turbine inlet)

- Collar (thrust)

- Gasket (oil inlet)

- Gasket (oil outlet

Some Helpful Tips You Can Follow

- Change the oil in your vehicle at least every 5000 kilometers.

- Only use oil that is recommended by the manufacturer of the engine.

- Do not use cleaning additives, these may loosen particles and other debris.

- Always let the engine warm up when you start. A recommended time is 30-60 seconds in warmer weather, and longer as the temperature drops.

- Remember, cold oil is thick, and doesn't flow as freely as warm oil.

- Do not "rev" your engine during the warm up, the turbo may not have had enough time to receive a full supply of oil.

- When stopping, let the engine idle for a period. The faster you were driving, the longer your idle down time should be.

- Remember, the turbo is free spinning at high RPMs, and when the engine is shut off, so is the oil supply. If the engine is not properly idled down, the turbo may experience bearing damage.

- When you do change the oil, remember to prime the filter and crank the engine without starting until full oil pressure is observed.

- These turbocharger installation instructions apply to ALL turbocharger's.

- Before fitting a replacement turbocharger, it is important to find the reason for the failure of the previous turbocharger and have the cause of failure rectified.

- Make certain all air inlet ducting as well as the exhaust manifold are clear of any foreign material which could cause extensive damage to the turbocharger.

- Take care to avoid any dirt or debris entering the turbocharger opening during fitting.

- Ensure all old gaskets have been completely removed from the exhaust flange as well as the oil feed and oil drain flanges.

- Inspect the oil lines for any kinks, blockages or other restrictions and replace if needed.

- Replace all gaskets and O-rings where applicable.

- Install the turbocharger onto the exhaust manifold.

- Fill the turbocharger oil feed hole with clean engine oil of the correct grade and spin the turbocharger by hand to allow oil to flow to the bearings. Refill the oil inlet hole and connect the oil supply line.

- Connect all other pipes onto the turbocharger.

- Fit a new air filter, oil filter and replace the engine oil to the vehicle manufactures specifications.

- Crank the engine without it starting, if possible, to allow oil pressure to build up.

- Start the engine, DON'T REV, and allow it to idle for 3 to 4 minutes.

- Check for any air or oil leaks and correct if any faults are found.

- You can now take your vehicle for a road test.